©2000-

Website Design by DESERT WEB MARKETING LLC.

Have a Product You think we should be using

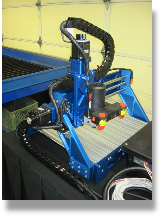

Cable management is critical in a project like this and even more so on larger machines. Without cable management damage to your critical control cables will result and it makes for a very confusing mess as well.

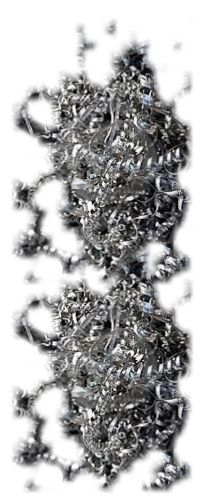

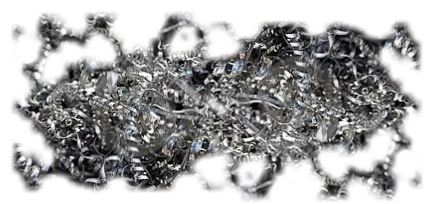

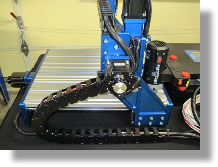

Our machine did not come with a cable management system. So it left its design all up to us, IE DIY. We love the Igus cable tracks that came with our Plasma machine and decided to order some for this project. Igus track is the Cadillac of cable management and can be very expensive. We went on eBay and found some for a very reasonable price. They appeared to be remnants from a larger job but we only needed two small sections so it was a perfect match. We selected 2 33” long by 1.5” square sections of Igus for this. One for the X axis and one for the Y axis.

We also invested in some plastic split loom wire cover in various sizes and some zip ties.

Because this cable management is custom DIY we needed to make some brackets to mount our Igus cable carrier. We drew up some simple mounts on Draw Plus and then cut them out on the Plasma Machine. A couple of bends and we had our mount.

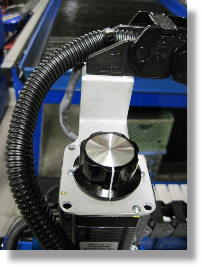

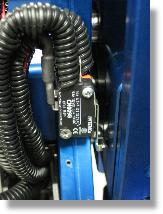

We used exiting holes in the top of the NEMA 23 motor on the Z axis to mount the bracket.

The Knobs are another EBay special. You saw in the first part of this build that our steppers had a dual shaft. We found these knobs on eBay for very cheap. They have two set screws for attaching to our ¼ stepper shafts. They work great for manually moving the axis and were great to have during setup.

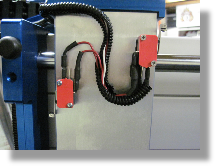

Above: Limit Switch mounts Right: Y axis bracket and Igus mount.

Above: Completed wiring and cable management Right: Y axis Igus mount.

Right: Back of X axis showing Igus track

Air / Coolant Nozzles

We wanted to add some Nozzles to allow us to blow air into the cut area for chip and debris removal or to flow coolant if we wanted down the road for machining aluminum.

We found our flexible nozzles on eBay and got the rest of our tube and brass fittings at our local hardware store. We have it set up only for air at this time but could convert it to flow cutting fluid down the road.

We had do make a custom mount to hold the assembly. We routed our small air line back through the cable track and will make the final connections later in the build.